Mud Pumps

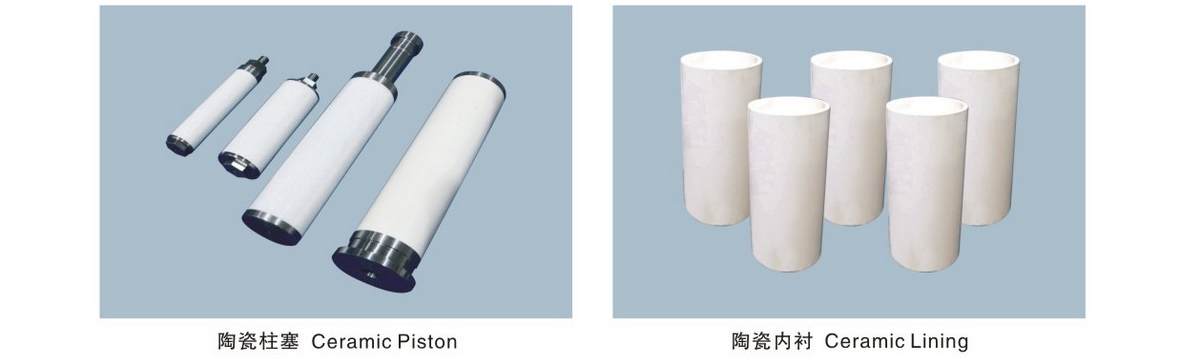

Ceramic Liners & Ceramic Pistons

The ceramic liner is made up of a metal shell and a high-wear-resistant ceramic lining which are fitted together through mechanical processing and hot charging. It is mainly used in offshore & onshore drilling and geological exploration. It has the properties of high strength, high toughness, wear resistance, high hardness, corrosion resistance, acid and alkali resistance, anti-static and super smooth surface, suitable for use in particularly adverse circumstances.

Features of Ceramic Liner

● Wear Resistance:

Compared with the traditional bi-metal liner, ceramic liner’s service life is 10 times longer and can be up to 4,000 hours.

● Surface Quality:

The ceramic lining has uniform microstructure. The surface undergoes rounds of fine machining and has excellent smoothness and gloss.

● Mechanical Properties:

By using the phase transformation toughening technology, the strength, hardness, toughness and thermal shock resistance of the material have been greatly improved, thus endows it with superior overall mechanical properties.

● Lower Costs:

Compared with the traditional bi-metal liner and single-phase alumina liner, the costs of the ceramic liner such as maintenance, labor, storage, transportation etc. are much lower.

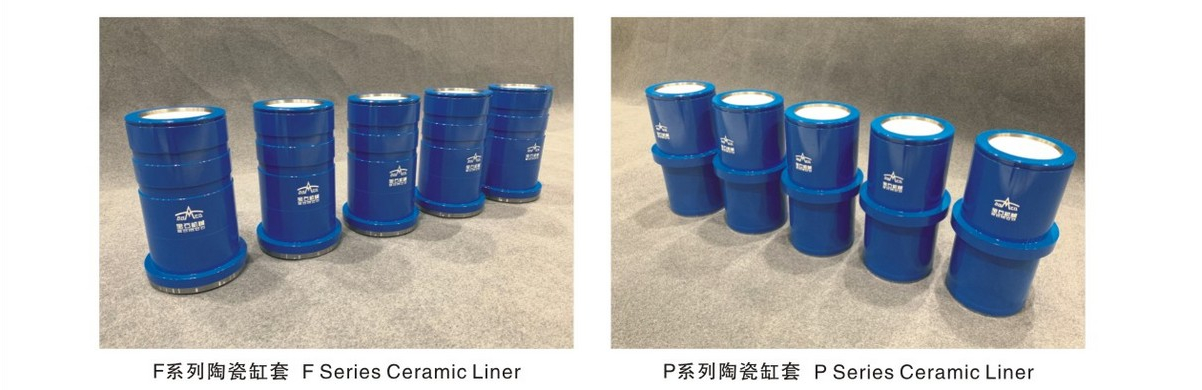

Types of Drilling Mud Pump Ceramic Liners

NO. | Types | |||

F1300/1600 | F800/1000 | F2200HL | F1600HL | |

1 | 4 1/2" | 4 1/2" | 130 | 130 |

2 | 5" | 5" | 140 | 140 |

3 | 5 1/2〃 | 5 1/2〃 | 150 | 150 |

4 | 6" | 6" | 160 | 160 |

5 | 6 1/2〃 | 6 1/2〃 | 170 | 170 |

6 | 7〃 | 110 | 180 | 180 |

7 | 130 | 120 | 190 | |

8 | 140 | 130 | 200 | |

9 | 150 | 140 | 210 | |

10 | 160 | 150 | 220 | |

11 | 170 | 160 | ||

12 | 180 | 170 | ||

Ceramic Liner Technical Parameters

Item | ZTA |

Ingredient | Zirconia |

Volume density, g/cm3 | ≧4.1 |

Flexural strength, MPa | ≧400-600 |

Fracture toughness, MPa.M1/2 | ≧4-6 |

Rockwell hardness, HRA | ≧88 |

Face roughness, µ m | ≦0.20 |

Compressive strength, MPa | ≧3000 |

Abrasion resistance, cm3 | 0.20 |

Thermal shock resistance | ≧450 ℃ |

Service life, h | ≧4000 |